Prdesrial Wet Ball Mill Quotes

.jpg)

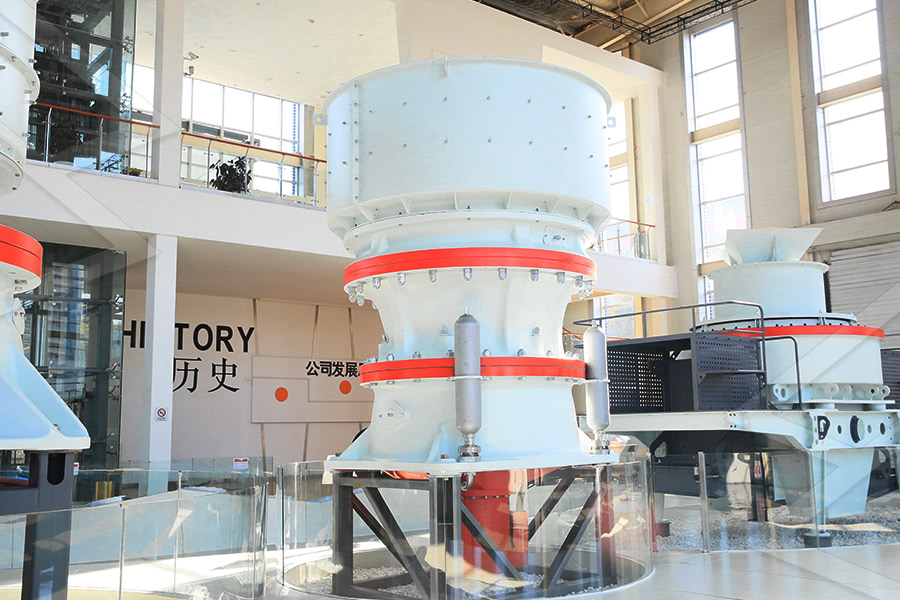

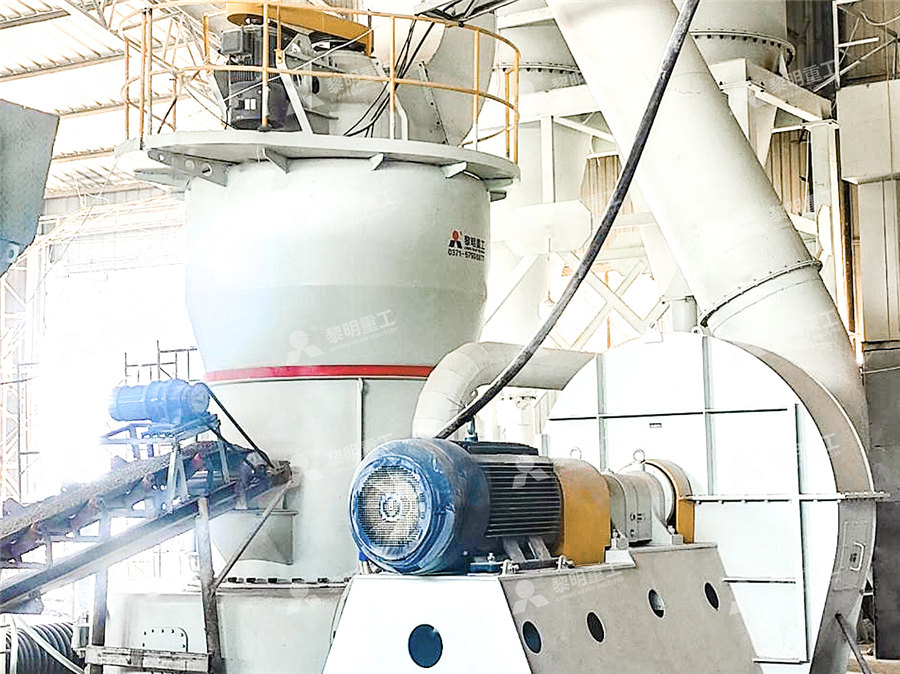

Mechanistic modeling and simulation of a wet planetary ball mill

2023年11月1日 — The present work deals with application of the mechanistic UFRJ mill model to describe size reduction in a planetary ball mill operating under wet conditions At first, noslip HertzMindlin contact parameters have been verified using the test rig 2021年11月17日 — 9 Citations Metrics Abstract This study investigates the effect of using ethanol as the process control agent during the wet ball milling of niobium (Nb) Dried Wet ball milling of niobium by using ethanol, determination 2012年11月1日 — Grinding media for ball mills ranges in size from 6 10 mm for most traditional applications and 15 20 mm for vertical mills Typical ball mills use highalumina or porcelain balls for their density, but wear is Modern Wet Milling and Material Processing2001年10月1日 — These laboratory tests give the data for the determination of the parameters of a ball mill model A set of scaleup criteria then scalesup these Modelbased procedure for scaleup of wet, overflow ball mills

.jpg)

Effect of parametric modeling of WET ballmilling on

2024年8月1日 — A novel environmentallyfriendly parametric modeling of wet ballmilling Na 2 CO 3 (aq) leaching at low temperature without roasting operation was carried out to 2021年5月20日 — power for the wet ball mill circuit (including ancillary equipment) is 3,802 kW compared to 1,893 kW for the dry Loesche VRM circuit The absorbed power for the A Technical and Economic Comparison of Wet Milling 2010年9月27日 — Architecture of soft sensor method for mill operating parameters variables subset and KPLS parameters simultaneously At last, a novel updating approach for (PDF) Modeling of operating parameters for wet ball millDue to the temperature rise induced by oblique balltoball and balltoreactor collisions during milling, acetone exhibited the best separation efficiency, achieving complete Onepot wet ballmilling for waste wireharness recycling

Impact of grinding balls on the size reduction of Aprepitant in wet

2024年4月8日 — Wet ball milling is a mechanical particle size reduction technique during which a suspension of drug particles and stabilizers is placed in a container alongside 2023年10月27日 — The performance of grinding media in a ball mill is measured in terms of wear rate, which is a function of the media composition, hardness, phase structure, and A Review of the Grinding Media in Ball Mills for Mineral 5 天之前 — DOVE Ball Mills are supplied in a wide variety of capacities and specifications DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h1000 g/h) Ball Mill Ball Mills Wet Dry Grinding DOVEExplore the working principle, types, parts, applications, advantages, and recent developments of ball mill grinding machines Discover how these versatile tools optimize grinding efficiency in various industries Versatility: Ball mills can perform various types of grinding, such as dry grinding ball mill or wet grid ball mill, batch or Ball Mill Grinding Machines: Working Principle, Types, Parts

36.jpg)

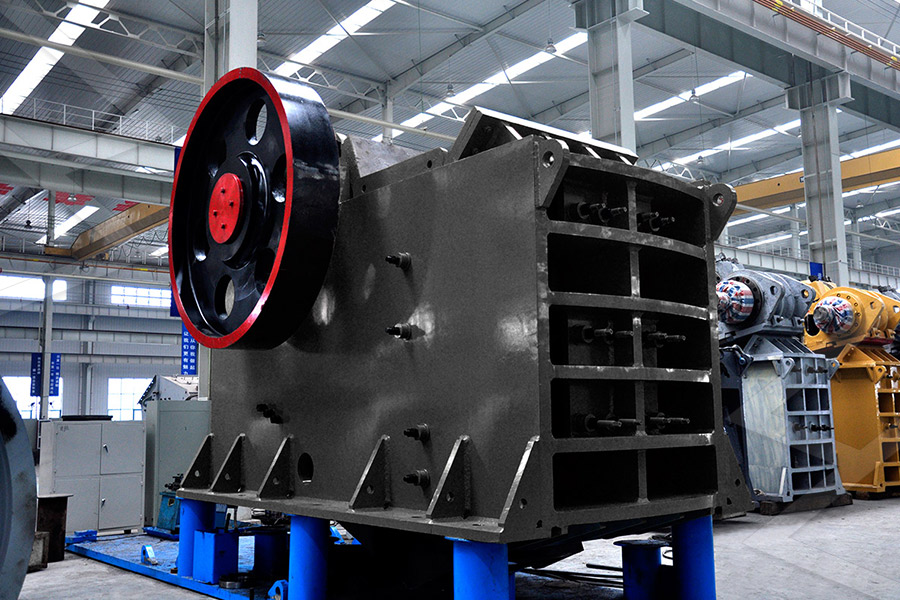

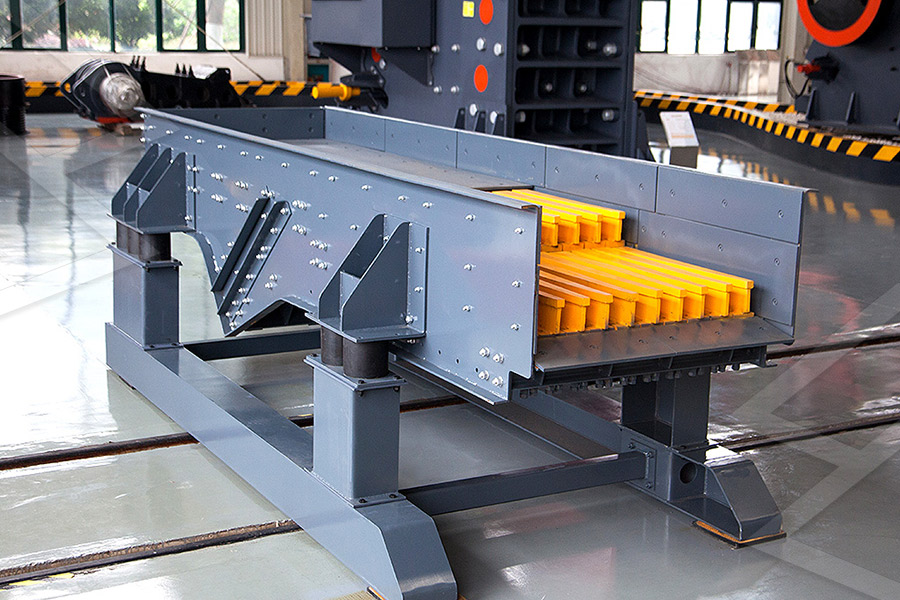

Ball Mills in the Mineral Processing Industry

2024年5月27日 — Loading the Mill: The ball mill is loaded with the material to be ground and the grinding media (balls) The material can be fed into the mill either wet or dry Rotating the Mill: Once loaded, the cylindrical shell Economy Ball Mill, a division of JSB Industrial Solutions, Inc manufactures Ball Mills that are diverse in applications and uses Since we are an OEM and our product line has been around for over 50 years, we can provide the experience and knowledge to enhance your process capabilities by applying our procedural based manufacturing methods to your Ball Mills Economy Ball Mill/JSB Industrial Solutions IncThe ceramic ball mill uses a ceramic material liner, and ceramic alumina balls are used as grinding media It is the key ball grinding mill equipment for fine grinding after the ceramic glaze is coarse grinding The ceramic ball mill machine is widely used for the dry or wet grinding of the ceramic glaze mineral raw materials, such as feldspar, quartz, talc, kaolin, Ceramic Ball Mill for Sale Buy Ceramic Ball ball mills 2024年8月8日 — Unlock the secrets to ball mill efficiency with our comprehensive guide on choosing the right grinding media Learn how material composition, size, shape, hardness, and cost impact your milling process and outcomes Get A Quote {{itemlabel}} {{vallabel}} AC3939 Alumina Wet Grinding Ball AC3938 Alumina Dry Grinding BallBall Mill Success: A StepbyStep Guide to Choosing the

Ball mills for sanitary ware production Setec

ALSING TYPE BALL MILLS Alsing type ball mills are used for wet grinding of solid materials, minerals, chemical products, ceramic glazes, pigments, etc in order to obtain, without pregrinding, homogeneous compounds free from external contamination Models up to 5000: support shoulders in metallic carpentry; transmission with gear reducer and 2024年9月7日 — The extremely high centrifugal forces of planetary ball mills result in very high pulverization energy and therefore short grinding times The PM 400 is a robust floor model with 4 grinding stations You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input The unique combination of high Ball Mills Glen Mills, Inc2012年11月1日 — Traditional Wet Milling The coatings industry is no different from others in its search for modern manufacturing techniques The traditional highspeed dissolver, ball mill, vertical mill and standard horizontal mill have been the primary methods used to mill pigmented materials for more than 50 years, and are still considered to be the industry Modern Wet Milling and Material Processing PCI MagRequest a quote to customize a ball mill grinder for your application Ball Mill Drums for Size Reduction Businesses across industries work with materials that come in large chunks or frequently clump together Ball mill drums offer an efficient and inexpensive way to grind materials down to a more usable size, often as fine as 2575 micronsIndustrial Ball Mill Grinders Pulva

Mini Ball Mill – Mineral Grinding Small Ball Mill

The mini ball mill is a type of smallscale ball mill, suitable for trial production and small batch production They can be used for both wet grinding and dry grinding Ball mill for sale! The small ball mill produced by AGICO Brief introduction The ball mill is the key equipment for crushing the material after it is crushed Ball mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizers, ferrous and non Ball Mill SBM Ultrafine Powder TechnologyHow to Select the Right Mill for Your Needs Having a laboratory mill on your premises offers a number of advantages, but you need the right equipment to get the most benefit from your investmentWhen evaluating lab mills, you should keep in mind the following considerations: SpeedEfficiencyBatch sizeMaterialStarting particle sizeTarget particle sizeProcess mode Choosing the Right Laboratory Ball Mills Union ProcessRequest a quote Create PDF Language: incl order data Download The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg Planetary Ball Mill PM 100 Wet and nanoscale grinding with the PM 100Planetary Ball Mill PM 100 RETSCH highest fineness

.jpg)

Small Ball Mill Mini Ball Mill for Small Scale Mineral Grinding

The small ball mill is a smallcapacity grinding equipment, which is defined relative to large ball millIt is generally suitable for smallscale production in the trial production stage Due to its small size and easy movement, small ball mill is sometimes referred to as mobile ball mill The mobile ball mill can be easily moved to the location of the material for onsite 2023年9月8日 — The main structure of the ball mill includes a solid cylinder, which contains grinding balls of different materials and sizes The motor and transmission system is used to drive the rotation of the cylinder, while the feeding and discharging system is responsible for the introduction of raw materials and the discharge of finished productsWhat Is An Industrial Ball Mill In The Food Industry2023年4月27日 — Overflow ball mill equipment can be divided into dry overflow ball mill and wet overflow ball mill according to the conveying form of the material to be ground In recent years, with the continuous development of grinding technology, wet grinding has become the mainstream process, and overflow ball mill equipment is widely used as the main How an Overflow Ball Mill Works? JXSC MineralSupplier of Continuous Feed Ball Mills for Wet Dry Grinding Applications Founded in 1984 with the acquisition of the EIMCO ball, pebble and rod mill product lines Neumann Machinery Company (NMC) is headquartered in West Jordan, Utah, in the USA just 14 miles south of Salt Lake CityBall Mill Manufacturer Neumann Machinery Company

.jpg)

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 — The grinding process can also take place in dry or wet conditions Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate on a variety of The grinding jars are arranged eccentrically on the sun wheel of the planetary ball mill The direction of movement of the sun wheel is opposite to that of the grinding jars in the ratio 1:2 (or 1:25 or 1:3) The grinding balls in the grinding jars are subjected to superimposed rotational movements, the socalled Coriolis forcesPlanetary Ball Mill PM 400 RETSCH powerful and quick 2024年9月8日 — The extremely high centrifugal forces of planetary ball mills result in very high pulverization energy and therefore short grinding times The PM 400 is a robust floor model with 4 grinding stations You may PM 400 Planetary Ball Mill Glen Mills, IncMeek Mill Quotes Quotes about: facebook; twitter; googleplus; Rap Sometimes I have to remind myself, that on my worst day I live like somebody on their greatest Meek Mill Sometimes, Worst, Worst Day TOP 25 QUOTES BY MEEK MILL AZ Quotes

Wet grid ball millProductsShandong Shankuang Machinery

ADD:No 11, ji'anqiao North Road, Jining City, Shandong Province Hotline:+86537 TEL:+86537 FAX:+86537 ZIP:Find here Ball Mills, Laboratory Grinding Mill manufacturers, suppliers exporters in India Mild Steel Wet Grinding Mill, For Coal Industry, Capacity(kg/hr): ₹ 25,00,000/Piece S S Planetary Ball Mill Get Quote Mild Steel Ball Mill Closed Circuit, For Pharmaceutical Industry, Capacity(kg/hr): 300 Ball Mills Laboratory Grinding Mill Latest Price, The ball mill can be operated in a wet or dry way, depending on the material properties and the intended use The wet ball mill is usually preferred when the material to be ground is wet, such as in the case of ore processing On the other hand, the dry ball mill is suitable for grinding dry materials, such as cement, limestone, and coal The Ultimate Guide to Understanding Ball Mill DiagramsPQN4 series planetary ball mills may be used for mixing, homogenizing, fine grinding, mechanical alloying, cell disruption, small volume hightech material production and even colloidal grinding They are the ideal wet/dry milling tools for acquiring research samples with high efficiency and low noise Vacuum jars may be used to process sample within a Across International PQN4 Four Liters Planetary Ball Mills (4

.jpg)

Ball Mills Suitable for every application Retsch

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications Dry and wet grinding by impact and friction ; To the product We bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications Classified depending on the circuit design, bearing, grinding type and drive, the selection is made on the basis of the product fineness, quality, and nature of raw material, site conditions and specific requirementsClosed and Open Circuits Ball Mill for Cement, Limestone, 2024年8月16日 — 175 Wall Street Glendale Heights, IL 60139 Phone: 18002377079 Fax: 6309240340 : info@shimpoceramicsChoosing Your Ball Mill NIDECSHIMPO CERAMICSCrushed ore is fed to the ball mill through the inlet; a scoop (small screw conveyor) ensures the feed is constant For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 3045%) Pulp (crushed ore and water) fills another 15% of the drum’s volume so that the total volume of the drum is 50% chargedBall Mill (Ball Mills Explained) saVRee saVRee

Planetary Ball Mill PM 300 RETSCH laboratory

The video shows wet grinding in the Planetary Ball Mill PM 100 Titanium dioxide in 125 ml Jar The graphic shows the result of pulverizing titanium dioxide (TiO2) at 650 rpm and 800 rpm in the PM 300 and the net Jar Mills are available in bench or floor models and have one to six jar capacities in 1, 2 or 3 tiers They are used for wet or dry grinding, mixing and blending of ores, chemicals, ceramics, glass, and more Benchtop Laboratory Ball Mills Bench and Floor Jar Mills2021年5月1日 — In this paper, a novel method of wet ball mill load identification based on CEEMDAN, RCMDE and SRNN is proposed Firstly, CEEMDANRCMDE is used to extract the load features of the ball mill Then, taking the advantage of SRNN's fast training speed and strong generalization ability, a mill load identification model based on SRNN is A method to identify wet ball mill’s load based on 2021年3月12日 — Ball mills and grinding tools Cement ball mills are typically twochamber mills (Figure 2), where the first chamber has larger media with lifting liners installed, providing the coarse grinding stage, whereas, in the second chamber, medium and fine grinding is carried out with smaller media and classifying linersBALL MILLS Ball mill optimisation Holzinger Consulting

05 TO 15 TPH SMALL SCALE MINER’S BALL MILL

In general, ball mills can be operated either wet or dry and are capable of producing products on the order of 100 um This duty represents reduction ratios as great as 100 Amount cannot be empty Request a Quote Category:Ball Mills, Grinding Mills Description Additional Information Description2023年6月12日 — A ball mill is a type of grinder that uses metal balls or other grinding mediums to reduce the size of various materials The material to be ground is placed in a cylindrical container that spins on its axis The metal balls or grinding media inside the container hits the material and breaks it down into smaller particlesWhat is a Ball Mill? Economy Ball MillHow Circulation Attritors Work The circulation grinding Attritor ("Q" machine) is a combination of an Attritor and a large holding tank which is generally about ten times the size of the Attritor The unique principle of the "Q" Attritor is the high circulating (pumping) rate, which results in a faster grind and a narrower particleWet Circulation Production Mills Union Process30 Best The Predators' Ball Quotes With Image The Predators' Ball is a nonfiction book by American journalist and author Connie Bruck, originally published in 1988 The book provides a riveting account of the rise and fall of junk bond king Michael Milken and the powerful investment firm Drexel Burnham Lambert At the center of the 30 Best The Predators' Ball Quotes With Image Bookey

.jpg)

QUOTES BY DAG HEWARDMILLS AZ Quotes

Dag HewardMills Quotes facebook; twitter; googleplus; The Holy Spirit has a sanctifying influence The influence of the Holy Spirit tends towards sanctification, purity and holiness Expect to live a life of greater purity, sanctification and holiness when under the sweet influence of the Holy SpiritOssian Everett Mills Quotes facebook; twitter; googleplus; So, let us, you and I, for the sake of our brother man, individually strive by example and influence to lift the standard of thought and conduct from the low level of selfishness and selfindulgence up to the lofty realms of aspirational thought and selfdenialQUOTES BY OSSIAN EVERETT MILLS AZ Quotes2023年12月28日 — 3 The ball mill is of good quality The better the quality of the ball mill, the more stable the performance of the ball mill will be during operation In addition, as for the lining plate of the ball mill’s wearing Factors Affect The Output and Quality of Ball 5 天之前 — DOVE Ball Mills are supplied in a wide variety of capacities and specifications DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h1000 g/h) Ball Mill Ball Mills Wet Dry Grinding DOVE

Inventory Of Common Faults And Solutions Of

4 天之前 — Reason: This is a common problem mining ball mills face, resulting in low productivity and low ore processing efficiency One reason may be the improper design of the grinding chamber, which affects the Explore the working principle, types, parts, applications, advantages, and recent developments of ball mill grinding machines Discover how these versatile tools optimize grinding efficiency in various industries Versatility: Ball mills can perform various types of grinding, such as dry grinding ball mill or wet grid ball mill, batch or Ball Mill Grinding Machines: Working Principle, Types, Parts 2024年5月27日 — Loading the Mill: The ball mill is loaded with the material to be ground and the grinding media (balls) The material can be fed into the mill either wet or dry Rotating the Mill: Once loaded, the cylindrical shell starts rotating around its horizontal axis Various mechanisms, such as gears, belts, or direct drives, can facilitate this rotationBall Mills in the Mineral Processing Industry MechProTechEconomy Ball Mill, a division of JSB Industrial Solutions, Inc manufactures Ball Mills that are diverse in applications and uses Since we are an OEM and our product line has been around for over 50 years, we can provide the experience and knowledge to enhance your process capabilities by applying our procedural based manufacturing methods to your Ball Mills Economy Ball Mill/JSB Industrial Solutions Inc

.jpg)

Ceramic Ball Mill for Sale Buy Ceramic Ball ball mills

The ceramic ball mill uses a ceramic material liner, and ceramic alumina balls are used as grinding media It is the key ball grinding mill equipment for fine grinding after the ceramic glaze is coarse grinding The ceramic ball mill machine is widely used for the dry or wet grinding of the ceramic glaze mineral raw materials, such as feldspar, quartz, talc, kaolin, Available cylinder sizes range from laboratory mills to 12′ in diameter Discharge Features For discharge of the product on wet grinding processes we offer our standard media retention grate along with an adequate size discharge valve For discharge of the product on dry grinding processes we offer our dry media retention grate and housing Orbis Machinery Ball Mills Ball Mill Drive2024年8月8日 — Unlock the secrets to ball mill efficiency with our comprehensive guide on choosing the right grinding media Learn how material composition, size, shape, hardness, and cost impact your milling process and outcomes Get A Quote {{itemlabel}} {{vallabel}} AC3939 Alumina Wet Grinding Ball AC3938 Alumina Dry Grinding BallBall Mill Success: A StepbyStep Guide to Choosing the 2023年8月23日 — A cement mill is a fundamental component of the cement manufacturing process, playing a vital role in breaking down and grinding cement clinker into fine powder This finely ground powder, when mixed with other materials, produces the building material we commonly know as cement To achieve this crucial transformation, a cement mill What Are the Parts of a Cement Mills? Cement Ball Mill