The Cost Of Crushing Rock Machine

Rock crusher production and operation cost analysis

2024年9月24日 — A rock crusher production and operation cost is the sum total of direct and indirect costs incurred in producing a rock crusher Direct costs include materials, labour, and overhead expenses while indirect costs include machine wear,2021年8月13日 — By implementing the cost calculation in Microsoft excel it would be more user friendly and applicable when calculating the cost in crushing and screening The Cost Analysis for Crushing and Screening Part II CORE2023年2月28日 — Learn about the factors that affect the price of stone crusher machines, the price range of these machines, and ways to save money when purchasing them This article also discusses the stone Stone Crusher Machine Price: Factors, Range, Title: Cost analysis for mineral processing – Development of methodology for determination of production cost for mineral fractions Abstract The purpose of this paper is to Cost Analysis for Crushing and Screening – Part I Lu

.jpg)

Crusher Operating Costs: How to Optimize and

2016年1月11日 — The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eighthour 2021年6月24日 — The cost of aggregate is not, in itself, a major factor in most applications, but its impact on the use of more expensive components, such as cement in concrete or Crushing and Screening Handbook AusIMM2023年2月23日 — How much does a rock crusher machine cost? The cost of a rock crusher machine varies depending on its size, features, and manufacturer However, the machine is a valuable investment that can The Rock Crusher Machine: A Revolutionary 2019年12月11日 — The outcome of the result was used to redesign and develop a prototype crushing machine with better output crushing pressure of 131×10 5 kN/m 2 and capable Performance optimization of jawtype rock crushing machine

How Much Does It Cost To Operate a Crusher?

Higher energy costs Often there is a justifiable case to spend additional capital dollars for the better machine When evaluating crushing equipment suppliers, crusher manufacturers should quantify both costs: purchase Replacing a Jaw Cone Crusher Setup by a Mobile Impact Crusher Improves Material Quality Total Operating Costs Impact crushers can be used in many rock crushing application in lieu of a jaw and impact Jaw and Cone Crusher Myths Total Operating 2021年6月24日 — with the right design for the most costeff ective crushing process We are the world’s leading supplier of both unit machines and complete aggregates processing systems Comprehensive process solutions Your system may involve a whole series of processes, such as crushing and screening, conveying, classifying, washing and pretreatment Crushing and Screening Handbook AusIMM6 天之前 — Superior’s Patriot Cone Crusher is an Americanmade, bushingstyle rock crusher that sets the standard for productivity and durability With a lifetime warranty and highgrade, industryexceeding components, the Patriot® Cone Crusher Superior Industries

The Complete Guide to Primary Crushing,

2023年2月28日 — Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working 2023年2月28日 — Learn about the factors that affect the price of stone crusher machines, the price range of these machines, and ways to save money when purchasing them This article also discusses the stone crusher machine market and key players in the industry ne 19F, Suite B, Global Trade Mansion, Wenfeng Avenue, Stone Crusher Machine Price: Factors, Range, and Ways to 2023年2月23日 — The rock crusher machine reduces mining costs by enabling mining companies to crush rocks onsite, eliminating the need to transport them to a crushing facility Conclusion: The rock crusher machine is a gamechanger for the mining industry, enabling efficient and effective crushing of rocks for various applicationsThe Rock Crusher Machine: A Revolutionary Equipment for Crushing 2024年7月17日 — Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stage

.jpg)

Ballast Stone Crushing Machine Price in Kenya Fote

2023年4月27日 — Building need in Kenya is high According to Kenya's 2016 economic report, the Kenyan construction industry is expected to grow at an average annual rate of 73% during 20152025, which sets a positive tone for Kenya's building materials boomHill Country Rock Milling specializes in rock milling, rock crushing, and rock grinding servicing all areas of the Texas Hill Country and beyond the increased cost of hauling in new material This machine can also be utilized to reestablish or create gravel access roads using the rocky materials available on your property Tired ofHill Country Rock Milling Rock Crushing FAIR OAKS, Texas2016年1月11日 — Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing The Experts: SandVik Mining + Metso and Quarry Academy = all agree The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eight Crusher Operating Costs: How to Optimize and Reduce2024年5月30日 — So, let’s embark on this journey to understand rock crushing equipment better Understanding Rock Crushing Equipment Rock crushing equipment is a broad term It refers to any machine that The Ultimate Guide to Rock Crushers Mellott

.jpg)

A New System to Evaluate Comprehensive

2019年12月5日 — The accurate performance evaluation of a cutterhead is essential to improving cutterhead structure design and predicting project cost Through extensive research, this paper evaluates the performance The Rebel Crusher is the perfect compact mobile crushing screening machine Crush rock, limestone, brick, concrete, asphalt Made in the USA! What are you looking for? Clear Crushing Screening Machines Rebel Crusher For Sale Rebel Concrete Crusher 2013年3月21日 — Mining crushers mainly include jaw crusher, cone crusher, impact crusher, mobile crusher for crushing stone, rock, quarry materials in mining industrycost of crushing rock Mining Quarry PlantExcessive energy consumption: Rock crushing equipment uses a lot of energy, which often results in high electricity costs Switching to a diesel/electricpowered machine is an excellent way to reduce energy consumption and operating expenses (OPEX)Rock Crushing 101: A Beginner's Guide Senya Crushers

.jpg)

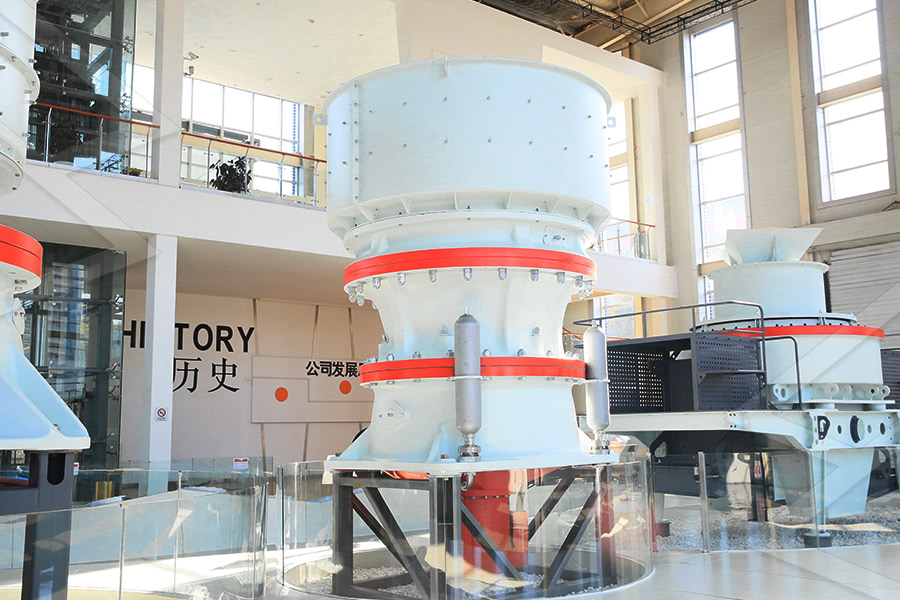

What Machines Do Stone Crushing Plants Need? Fote

2024年3月1日 — Hammercrushing machines are simple and compact in design, robust in construction, powerful, safe, and low maintenance They are particularly suitable for crushing mediumhard rock They are used exclusively in a fixed or semimobile mode The equipment is simple and compact in design, robust in construction, powerful, safe, and Our constantly evolving offering for mining and rock drilling, crushing machine Support telephone KSh 14,456,000 Mining Mobile Stone Crusher Plant Jaw Crushing Station in KE Gold Ore Jaw Crusher Machine Big Mouth PE1000*1200 180TPD Complete Stone Rock Crushing Line Price for Mining Mining Mobile Stone Crusher Plant Jaw Crushing Station Stone Crusher Manufacturing Equipment in Kenya Jijicoke4 天之前 — Automatic variable speed VGF ensures continuous choke feeding of the crushing chamber for optimal productivity ‘HardRock’ Quarry application, 60mm (2 1/2”) ‘SoftRock’ Quarry application The Finlay® J1170AS+ provides the flexibility of a jaw crushing and screening plant on one machine This highly productive machine J1175 Tracked Jaw Crusher Rock Crushing Machine Finlay2018年8月7日 — Rock crushing machines are highly essential in the mineral processing and extractives industries The few machines in use toda y in most industries are imported, thus raising the cost of (PDF) Design and Construction of Rock Crushing Machine

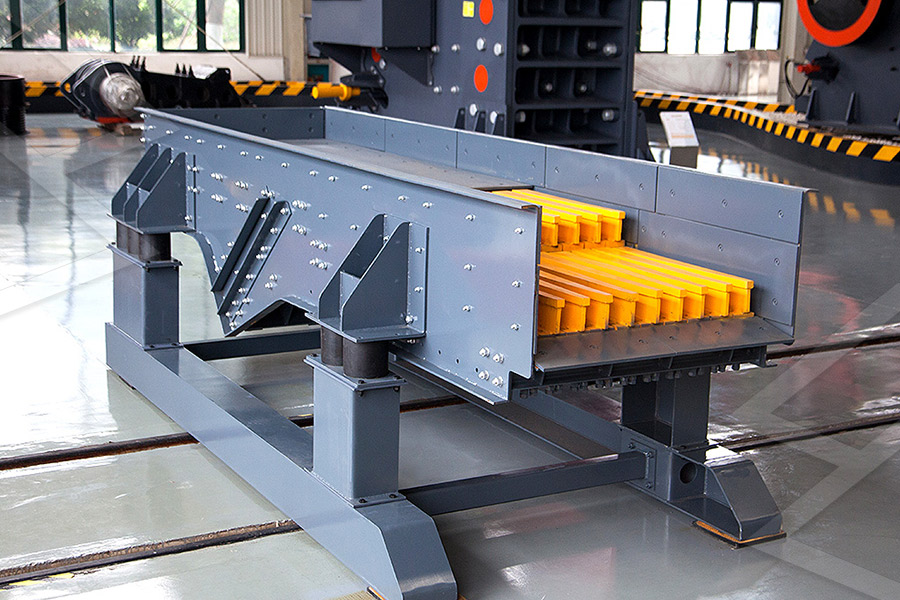

Factors affecting the performance of crushing plant operations

2014年1月1日 — To achieve optimal performance of a crushing plant, not only the design of the individual machines but also the cost of running them should be taken into accountIn this paper a novel method for 2023年2月23日 — If you're in need of onsite crushing capabilities, a portable rock crusher for sale may be the solution you're looking for In this comprehensive guide, we'll cover everything you need to know about Your Ultimate Guide to Buying a Portable Rock 2022年11月21日 — This is completed by using a rock crusher that can handle the smallest rocks The most common type of rock crushing machine used for tertiary crushing is a hammer mill Key Considerations Operational Everything You Should Know About Rock 2016年4月7日 — Most aggregate producers are well acquainted with the selection of crushing equipment, and know it is possible to select a piece of equipment based solely on spec sheets and gradation calculations Selecting the right type of crushing equipment

Rock Crusher Eastman Rock Crusher

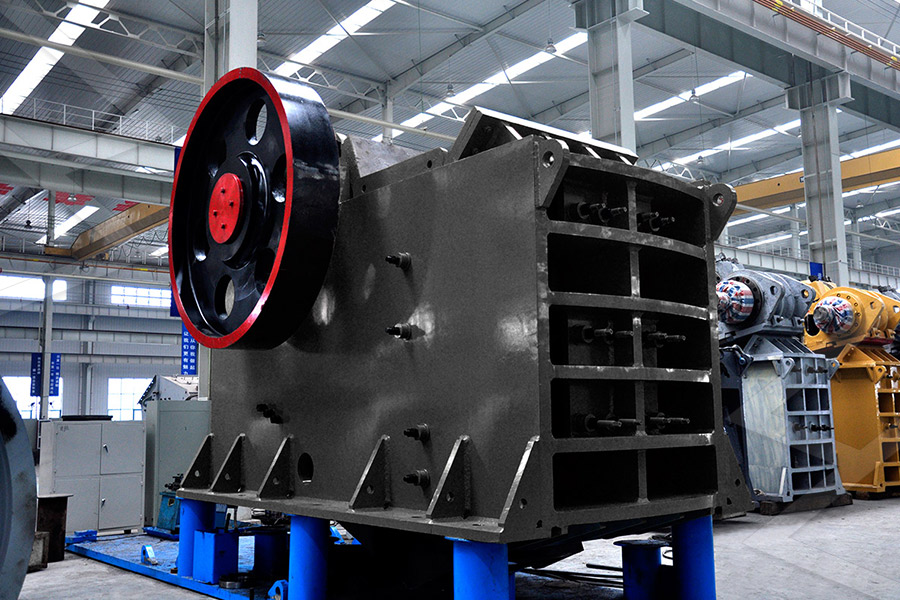

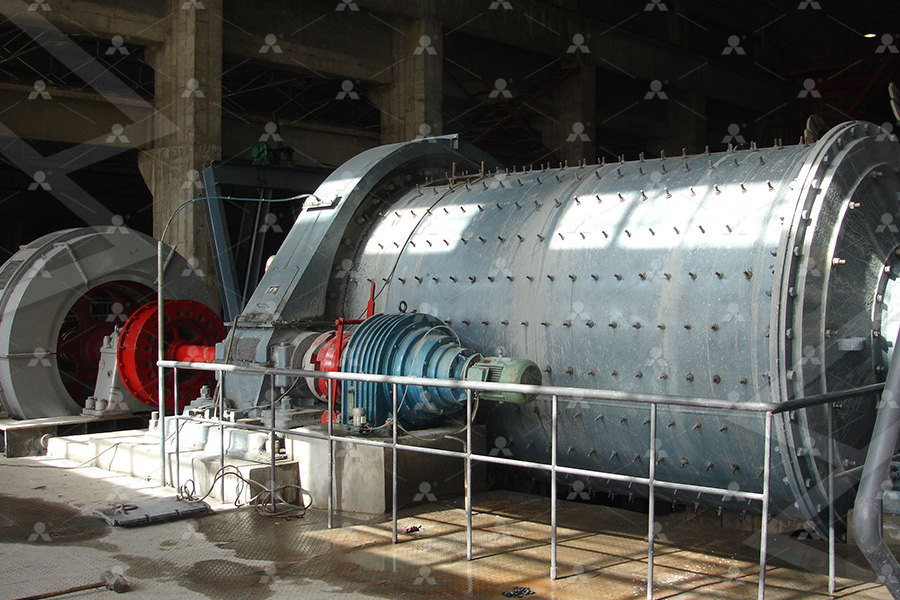

Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industriesAt present, there are two types of stone crushing machines commonly used: mobile stone crushers and stationary stone crusher equipment Stationary crushers include jaw crushers, impact The first United States patent for a rock crushing machine was in 1830 Its key technology was the drop hammer concept, found in the wellknown stamp mill, which would be repeatedly linked to the golden age of mining Portable crushers also contribute to cost savings by reducing transportation expenses and time Recycling Industry: Types of Crushers: What You Need to Know Machinery Finding the right size reduction machine for your industry is important Williams impact crushers aid in this decision by delivering uniform finished products with our consistent ability to break apart material Easy Maintenance Williams machines have been designed with easy maintenance requirements to increase efficiency and decrease overall Impact Crusher Machines Williams Patent Crusher2023年3月6日 — As experience shows, when one determines the energypower parameters of crushing and grinding processes by using the existing methods, the power of motors used in drives of existing crushers of various types often turns out to be excessive [10, 11]In this case, the drive will operate at a relatively low load (ratio of the power consumed by the Study of the EnergyPower Parameters of the Crushing

Onsite Crushing Guide Download Free Cost Calculator

Onsite crushing works for small and large contractors DOWNLOAD YOUR FREE COST CALCULATOR Onsite crushing turns up to 30% of your material disposal costs into profits Concrete Asphalt Rock Get your RUBBLE MASTER so that you can service the machine easily from the ground and feed it easily in confined areas and with smaller 2021年8月13日 — II Abstract Sandvik SRP has earlier studied a new way of calculating the cost in crushing and screening the results was a satisfactory, Sandvik SRP is now ready to go further inCost Analysis for Crushing and Screening Part II CORE2019年12月11日 — The outcome of the result was used to redesign and develop a prototype crushing machine with better output crushing pressure of 131×10 5 kN/m 2 and capable of crushing 425–569 kg of rock per hour, depending on the type of rock to be crushed The machine performed exceptionally well with an efficiency of 95% and is relatively durable Performance optimization of jawtype rock crushing machine 2019年11月4日 — Jaw crushing should reduce the granularity of granite as much as possible, and the impact crusher will shape the crushing, so as to achieve the crushing effect of excellent particle size and appropriate Granite Rock Crushing Flow Price JXSC

Crushing Equipment Superior Industries US

4 天之前 — A brand of aggregate crushing equipment engineered via the voice of the customer: Liberty™ Jaw Three Cone Crushers Valor™ VSI Sentry™ HSI Chips, Concrete Rock, Cubicle Products, Fractured 2024年9月24日 — %PDF12 %âãÏÓ 114 0 obj /Linearized 1 /O 116 /H [ 1107 524 ] /L /E 29615 /N 29 /T >> endobj xref 114 34 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n Crushing Plant Design and Layout Considerations2023年5月12日 — The above is a brief introduction of the 6 popular granite crushers on the market To achieve efficient granite rock crushing, the following factors should be considered 1 Wearresistance Granite rock has high hardness and high silicon content It is difficult to crush or requires relatively high crushing costs6 Granite Crushers for Efficient Granite Rock Crushing2008年8月1日 — The reduction ratio in the preceding crushing circuit is about 40–100, from typically blast rock of maybe 200–500 mm down to the 5 mm particles fed to the grinding mill But in a mine, the cost and energy consumption associated with fine grinding are considerably larger than those associated with the compressive crushingEnergy considerations in compressive and impact crushing of rock

.jpg)

The Stages of Rock Crushing Mellott

2023年1月2日 — Understanding the different stages of rock crushing is essential so that your projects run smoothly and cost effectively while also maximizing the lifespan of your equipment What Are the Stages of Rock Crushing? Rock crusher machines are a key tool in mining and construction operations These machines operate within a few different stages:2019年8月24日 — Rock crushing machines are highly essential in the mineral processing and extractives industries The few machines in use today in most industries are imported, thus raising the cost of production and depleting foreign exchange earnings Locally designed rock crushing machines have lot of benefits which translate to job creation, revenue Design and Construction of Rock Crushing Machine from 2017年8月28日 — Thus five additional machines will cost 2750 rubles According to data from the TemirTau dolomite quarry of the GU KMK, the total cost of the plant with one hammer was 5505 rubles, or without the hammer at 550 rubles, the Thus the norm for manual crushing of oversize rock is 7fi tons per shift If the ore contains 12% oversize, this mine Calculating the efficiency of crushing plant SpringerAs with jaw crushers, these machines are compression crushers that use a stationary and moving piece of steel to break up the material Cone crushers use a rotating head to crush the rock within a steel bowl After initially being broken down in this manner, the material will travel through a narrow opening at the bottom of the bowl to achieve a finer grain sizeHow to Choose a Rock Crusher PowerScreening Equipment

.jpg)

CRUSHING SCREENING Crushing and Screening

2017年5月30日 — with a unique rockonrock crushing principle, which significantly reduces the wear costs while offering superior cubical shape for the best quality fine aggregate production VSI crushers are usually used in the final stages of the crushing process to shape flat material in quarries and to prepare materials for grinding in the mining industry In2021年6月24日 — with the right design for the most costeff ective crushing process We are the world’s leading supplier of both unit machines and complete aggregates processing systems Comprehensive process solutions Your system may involve a whole series of processes, such as crushing and screening, conveying, classifying, washing and pretreatment Crushing and Screening Handbook AusIMM6 天之前 — Superior’s Patriot Cone Crusher is an Americanmade, bushingstyle rock crusher that sets the standard for productivity and durability With a lifetime warranty and highgrade, industryexceeding components, the Patriot® Cone Crusher Superior Industries2023年2月28日 — Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working The Complete Guide to Primary Crushing,

Stone Crusher Machine Price: Factors, Range, and Ways to

2023年2月28日 — Learn about the factors that affect the price of stone crusher machines, the price range of these machines, and ways to save money when purchasing them This article also discusses the stone crusher machine market and key players in the industry ne 19F, Suite B, Global Trade Mansion, Wenfeng Avenue, 2023年2月23日 — The rock crusher machine reduces mining costs by enabling mining companies to crush rocks onsite, eliminating the need to transport them to a crushing facility Conclusion: The rock crusher machine is a gamechanger for the mining industry, enabling efficient and effective crushing of rocks for various applicationsThe Rock Crusher Machine: A Revolutionary Equipment for Crushing 2024年7月17日 — Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stage2023年4月27日 — Building need in Kenya is high According to Kenya's 2016 economic report, the Kenyan construction industry is expected to grow at an average annual rate of 73% during 20152025, which sets a positive tone for Kenya's building materials boomBallast Stone Crushing Machine Price in Kenya Fote

Hill Country Rock Milling Rock Crushing FAIR OAKS, Texas

Hill Country Rock Milling specializes in rock milling, rock crushing, and rock grinding servicing all areas of the Texas Hill Country and beyond the increased cost of hauling in new material This machine can also be utilized to reestablish or create gravel access roads using the rocky materials available on your property Tired of2016年1月11日 — Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing The Experts: SandVik Mining + Metso and Quarry Academy = all agree The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eight Crusher Operating Costs: How to Optimize and Reduce