Mining Ball Mill In Netherlands Antilles

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 — Ball mill efficiency directly affects the cost of mineral processing Grinding media play a vital role in enhancing the efficiency of a ball mill through their direct effect Ball mills are the most common grinding machine employed in the mining industry Grinding occurs in a single stage, or multiple stages Multiple stages may include a rod mill followed by a ball mill (two stage circuit), or Ball Mill (Ball Mills Explained) saVRee saVRee2023年2月1日 — open access Abstract This article presents a novel approach to integrate a throughput prediction model for the ball mill into shortterm stochastic production Integrating geometallurgical ball mill throughput predictions 2017年6月2日 — Ball mills use a tumbling process with stone or metal balls as the grinding materials to reduce the coarse material by means of impact and friction Ball mills typically use water or other liquid and additives to How it Works: Crushers, Grinding Mills and

Ball Mill Grinding Machines: Working Principle, Types, Parts

Planetary ball mills are ideal for nanoscale grinding and mixing Vibratory Ball Mills: Utilizing vibrations, these mills are suitable for ultrafine grinding and mixing of materials Applying steel balls as grinding media, our ball mills or ball grinding machines are widely applied in mining, construction, and aggregate applications Our ball mill for sale are engineered for highefficiency Ball Mills Manufacturer JXSCMagotteaux grinding media, end wall and liners in a mining ball mill Magotteaux's areas of expertise on a mining flowsheet The MagotteauxMillreg; is a test mill, which reproduces in the laboratory the Magotteaux Mining Technology2012年6月1日 — The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Basic kinetic and (PDF) Grinding in Ball Mills: Modeling and Process Control

Realtime reconciliation of a geometallurgical

2018年3月14日 — The ball mill is usually the largest energy consumer at a mine site and significantly affects operational expenditures Given a target particle size, Bond Mill Work Index estimates are used to predict a ball 2023年4月30日 — Structure and Principle The ball mill in a concentrator is mainly composed of feeding part, discharging part, rotating part, and transmission part (speed reducer, Ball Mill SpringerLinkThe BM450 Mixer/Mill (part #8000D), is a highenergy ball mill with dual clamps that grinds up to 02 10 grams of dry, brittle samples It r educes samples to analytical fineness and can be utilized for mechanical BM450 Mixer/Mill – Dual clamp, highenergy 2024年7月2日 — By adjusting the gradation of the steel balls, the size and amount of the discharge fineness can be changed The highefficiency and energysaving ball mills produced by our company are all supported by rolling bearings instead of bearing bushes and sliding bearings Compared with the coaxial pad sliding beaning supported energy Ball MillGrinding EquipmentHongji Mine Machinery

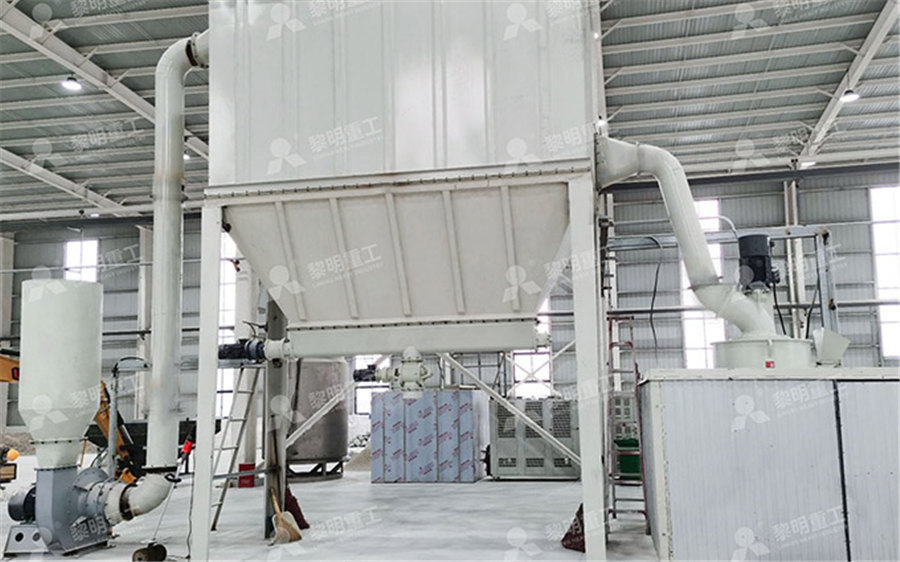

vertical roller mill in netherlands antilles Heatcon Mining

2023年7月26日 — Webcoal pulverizer designs are Vertical Roller Mills Figure 2 shows a cutaway view of a Babcock and Wilcox MPS Pulverizer RingRoll and BallRace Mills A ball or roller between two races or rings provides the grinding surfaces on which pulverization occurs One or both of the races may rotate against a ball or roll (in a Read MoreApplications of AG Mills in Mining AG mills are widely used in mining operations around the world, as they are essential for reducing the size of ore and preparing it for further processing As a ball mills supplier with 22 years of experience in the grinding industry, we can provide customers with types of ball mill, vertical mill, rod Basics and Their Role in Mining Operations ball mills supplierRetsch Planetary Ball Mill, Model PM 100 CM Used Retsch planetary ball mill, model PM 100 CM, includes 500ml Stainless chamber, 1250 watts, 120 volt, part# 205200003, serial# A, built 2010Used Ball Mills for sale in USA MachinioBall mills are used for grinding and mixing materials, and they can be found in a variety of industries, from mining and construction to pharmaceuticals and ceramics In this guide, we’ll explore the basics of ball mills, including how they work, the different types available, and what to look for when you’re shopping for a ball mill for A Comprehensive Guide to Finding the Best Ball Mill for Sale

mill/sbm heavy mining equipment for sale in netherlands antilles

You've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity2024年9月22日 — Ball Mills: Ball mills are the most commonly used type of grinding mill They work by rotating a cylinder containing lead balls, called grinding media, at speeds of up to 700 revolutions per minute The ore is fed into the mill and as the cylinder rotates, the balls crush and grind the ore, causing the particles to break down in size Rod Mills:Understanding the operation of grinding mills in the mining 13′ X 21′ ALLIS CHALMERS BALL MILL, 2000 HP used Manufacturer: AllisChalmers Description 13′ x 21′ Allis Chalmers Ball Mill, 2000 HP Motor with Controls, Rubber Liners, Lubrication SystemsUsed Ball Mills (mineral processing) for sale in Ontario, 2023年11月23日 — Boosting productivity and quality in mining operations is a priority for many companies, and one of the key elements in achieving this goal is the use of highquality grinding media, specifically steel grinding ballsThese balls play a crucial role in the grinding of raw materials in cement plants, energy generating companies, ore mining, Steel Grinding balls an optimal choice for mining in ball mills

.jpg)

The significance of gold mining ball mills in the modern mining

2024年9月22日 — Gold mining ball mills are grinders that are used to reduce the size of ore materials by means of compression and impact They are cylindershaped devices, filled with grinding balls, which rotate on a horizontal axis As the balls move around the cylinder, they crush and grind the ore materials, resulting in a fine powder 2024年5月27日 — The General Function of Ball Mills A ball mill is a grinder used for grinding and blending materials for mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering Ball Mills in the Mineral Processing IndustryBall Mills are key in industries like mining and construction, efficiently grinding materials into fine powder using impact and friction, making them a versatile choice for material size reduction EXPLORING THE AM King's Ball Mills Perfect for Mining and 2023年2月1日 — Comminution performance of the mineral reserve is conventionally assessed by different hardness and grindability indices Lynch et al [12] reviewed the mostly used indices to date, including Bond’s Ball Mill Work Index (Wi), the SAG Power Index (SPI), the Drop Weight Index (DWi) and the resistance to impact breakage (A × b) To date, the Integrating geometallurgical ball mill throughput predictions

.jpg)

Google Translate

Google's service, offered free of charge, instantly translates words, phrases, and web pages between English and over 100 other languagesBM200 Mixer/Mill Operation Manual; BM400 Mixer/Mill Operation Manual; BM450 Mixer/Mill Operation Manual; BM400 and BM450 Mixer/Mill Accessory Manual; BM450 Mixer/Mill High Energy Ball Mill Quick Start Guide; Mechanical Alloying with the ColeParmer Mixer/Mill; Spex SamplePrep to ColeParmer Model Rebrand Cross ReferenceBM200 Mini Mixer/Mill (part #5120) ColeParmerRetsch Planetary Ball Mill, Model PM 100 CM Used Retsch planetary ball mill, model PM 100 CM, includes 500ml Stainless chamber, 1250 watts, 120 volt, part# 205200003, serial# A, built 2010Used Ball Mills for sale Paul O Abbe and US Stonewareallis chalmers svedala ball mill, year 1979 rebuilt 1998 used manufacturer: allischalmers; reference number: tt1812 allis chalmers svedala ball mill, year 1979 rebuilt 1998 allis chalmers svedala ball mill 13’ diameter x 21’ long rubberlined mill with siemensallis 2,000 hp 4000 volt 200 rpm sUsed Ball Mills (mineral processing) for sale in USA Machinio

.jpg)

SAG Mill and Ball Mill Case Study Mining Technology

In September 2011, the company Outotec, located in Espoo (Finland), awarded Ingeteam a contract for the design and supply of the main drive equipment for a 23MW SAG mill and a 21MW ball mill to be installed in Russia2012年6月1日 — As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and (PDF) Grinding in Ball Mills: Modeling and Process ControlThe ball mill is a common grinding equipment, widely used in industries such as mining, building materials, and chemical engineering for material grinding The maintenance of the ball mill is of great significance in ensuring the normal operation of the equipment, extending the equipment lifespan, and improving production efficiencyBall Mill Maintenance Process and Methods Miningpedia2024年1月13日 — Table 1 Chemical composition of typical grinding media (% wt) Adapted from [24] 211 Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in Grinding Media in Ball MillsA Review ResearchGate

.jpg)

Exploring Ball Mill Diagram: A Comprehensive

2024年4月28日 — Alongside the mining industry, ball mills are also used in different sectors, such as cement production, for grinding clinker and other raw materials; ceramic manufacturing, for grinding and mixing ceramic 2024年4月28日 — Critical Speed: Critical speed is the hypothetical speed at which the centrifugal force is equal to the gravitational force, and the grinding media starts sticking to the inner shell of the equipment instead of falling freelyGrinding at or close to critical speed of the mill yields a poorer grinding efficiency The ball mills are mostly operated at 65 What is a Ball Mill Explained: InDepth Guide JXSCHorizontal Ball Mill ISO9001 Certificated Horizontal Ball Mill Grinding Machine High Performance Wet Horizontal Ball Mill 80kw For Gold Plant Raw Material Ball Mill Machine Mineral Processing Equipment 185kw2300kw Cone Crusher Machine Mining Spring Cone Crusher Machine 30kw 55kw With AC Motor TypeQuality Mining Ball Mill Cement Ball Mill factory from China2023年12月28日 — 3 The ball mill is of good quality The better the quality of the ball mill, the more stable the performance of the ball mill will be during operation In addition, as for the lining plate of the ball mill’s wearing parts, the quality of the lining plate affects the overall production efficiency of the ball mill As we all know, the lining Factors Affect The Output and Quality of Ball Mills And How

.jpg)

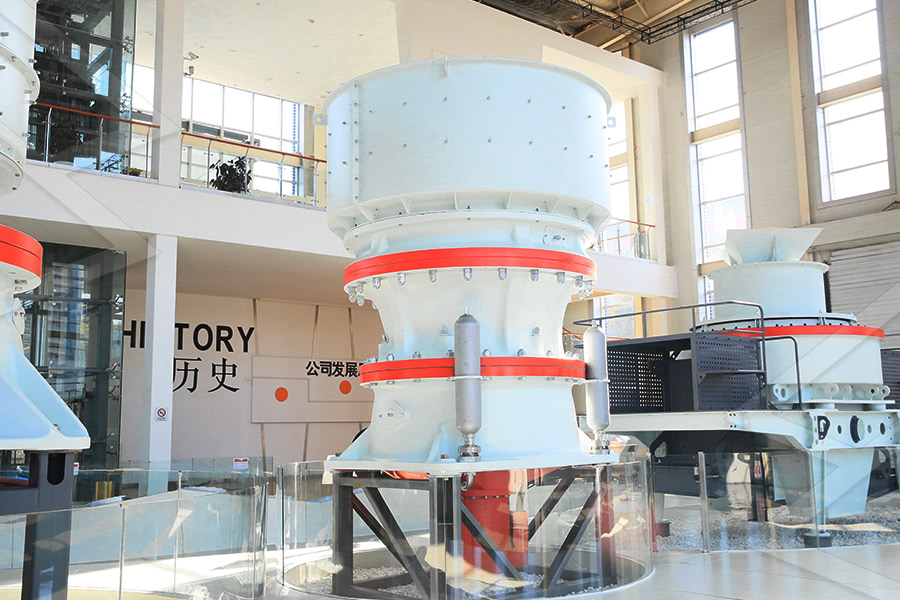

Grinding Mills Mineral Processing Equipment CITIC HIC

2024年9月12日 — High costeffectiveness CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product CITIC HIC is responsible for setting the national standards of semiautogenous mills (SAG mills) and ball mils, supported by powerful database, optimized process technology, cuttingedge design concept, and 60 Mill Type Overview Three types of mill design are common The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns; The CenterPeriphery Discharge mill has feed reporting from both AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill 2020年5月11日 — 2019 caterpillar caterpillar 336 next gen excavator 336 next genKeeping those ball mills turning Australian MiningThe BM400 Mixer/Mill (part #8000M), is a highenergy ball mill that grinds up to 02 10 grams of dry, brittle samples The vial, which contains a sample and one or more balls, is shaken in a complex motion that combines backandforth swings with short lateral movements, each end of the vial describing a figure8BM400 Mixer/Mill –Single clamp, highenergy ball mill,

Ball Mills – Sandrock Mining

2024年9月3日 — The ball mill is used to grind many kinds of mine and other materials, or to select the mine 6 Ball mill is widely used in the mining industry, chemical industry, etc 7 There are two ways of grinding: the Browse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Also the Premier™ mills and Select™ mills come ready to be easily integrated Grinding mills for mining and minerals mills The mills in mining operation grind the product from the crushers to fine material ready for treatment Rod mills, ball mills, autogenous mills, and semiautogenous mills (SAG Mills) all have a number of lubricating and Ensure clean dry oil on rod mills, ball mills, How Mining and Sustainability Can Work Together Benefits of Surplus Mining Equipment What is the Circular Economy? Case Studies; About; (FullerTraylor) 22' x 365' (67m x 11m) Ball Mills with Dual ABB 4,900 kW (6,662 HP) Motor Drives ACS 6000 ABB Variable Frequency Drives Manufacturer: FLSMIDTH Location: North America Inventory ID Used Ballmills For Sale AM King

ball mill prices and for sale netherlands antilles

Ball Mill Used For Dolomite In Grinding Egypt 1,875 dolomite ball mill products are offered for sale by suppliers on, of which mine mill accounts for 11, grinding equipment accounts for 1 a wide variety of dolomite ball mill options are available to you, such as more than 5 years, 6 months you can also choose from none, egypt, and canada dolomite ball mill, as2024年9月9日 — A ball mill, also known as a ball grinding machine, is a wellknown ore grinding machine widely used in mining, construction, and aggregate applicationsJXSC started the ball mill business in 1985, supplying global services including design, manufacturing, installation, and free operation trainingBall Mills Industry Grinder for Mineral Processing JXSC 2024年8月13日 — Base Metal Mining: Ball mills are also essential in base metal mining, such as copper, zinc, and lead These mills are used to grind and process the ore, facilitating the extraction of the valuable metals The fine particle size obtained by the ball mill improves the efficiency of subsequent extraction and refining processes 3 Aggregate The role and importance of ball mills in the mining industry2023年5月27日 — 1) Horizontal Ball Mill Horizontal ball mills are the most common type of ball mill They are used in the mining and manufacturing industries to grind materials into fine powders The horizontal ball mill consists of a rotating drum with a series of balls inside When the drum rotates, the balls fall onto the material to be ground and crush Ball Milling in Lithium Ore Processing: A Comprehensive Guide

.jpg)

Grinding in Ball Mills: Modeling and Process Control

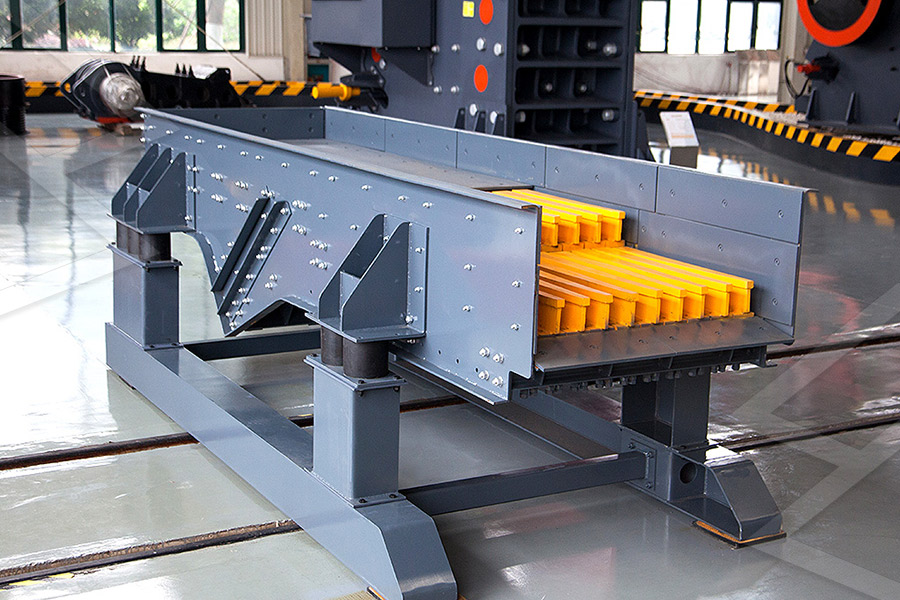

There are three types of grinding media that are commonly used in ball mills: • steel and other metal balls; • metal cylindrical bodies called cylpebs; • ceramic balls with regular or high density Steel and other metal balls are the most frequently used grinding media with sizes of the balls ranging from 10 to 150 mm in diameter [30]The BM450 Mixer/Mill (part #8000D), is a highenergy ball mill with dual clamps that grinds up to 02 10 grams of dry, brittle samples It r educes samples to analytical fineness and can be utilized for mechanical BM450 Mixer/Mill – Dual clamp, highenergy 2024年7月2日 — By adjusting the gradation of the steel balls, the size and amount of the discharge fineness can be changed The highefficiency and energysaving ball mills produced by our company are all supported by rolling bearings instead of bearing bushes and sliding bearings Compared with the coaxial pad sliding beaning supported energy Ball MillGrinding EquipmentHongji Mine Machinery2023年7月26日 — Webcoal pulverizer designs are Vertical Roller Mills Figure 2 shows a cutaway view of a Babcock and Wilcox MPS Pulverizer RingRoll and BallRace Mills A ball or roller between two races or rings provides the grinding surfaces on which pulverization occurs One or both of the races may rotate against a ball or roll (in a Read Morevertical roller mill in netherlands antilles Heatcon Mining

Basics and Their Role in Mining Operations ball mills supplier

Applications of AG Mills in Mining AG mills are widely used in mining operations around the world, as they are essential for reducing the size of ore and preparing it for further processing As a ball mills supplier with 22 years of experience in the grinding industry, we can provide customers with types of ball mill, vertical mill, rod Retsch Planetary Ball Mill, Model PM 100 CM Used Retsch planetary ball mill, model PM 100 CM, includes 500ml Stainless chamber, 1250 watts, 120 volt, part# 205200003, serial# A, built 2010Used Ball Mills for sale in USA MachinioBall mills are used for grinding and mixing materials, and they can be found in a variety of industries, from mining and construction to pharmaceuticals and ceramics In this guide, we’ll explore the basics of ball mills, including how they work, the different types available, and what to look for when you’re shopping for a ball mill for A Comprehensive Guide to Finding the Best Ball Mill for SaleYou've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activitymill/sbm heavy mining equipment for sale in netherlands antilles

Understanding the operation of grinding mills in the mining

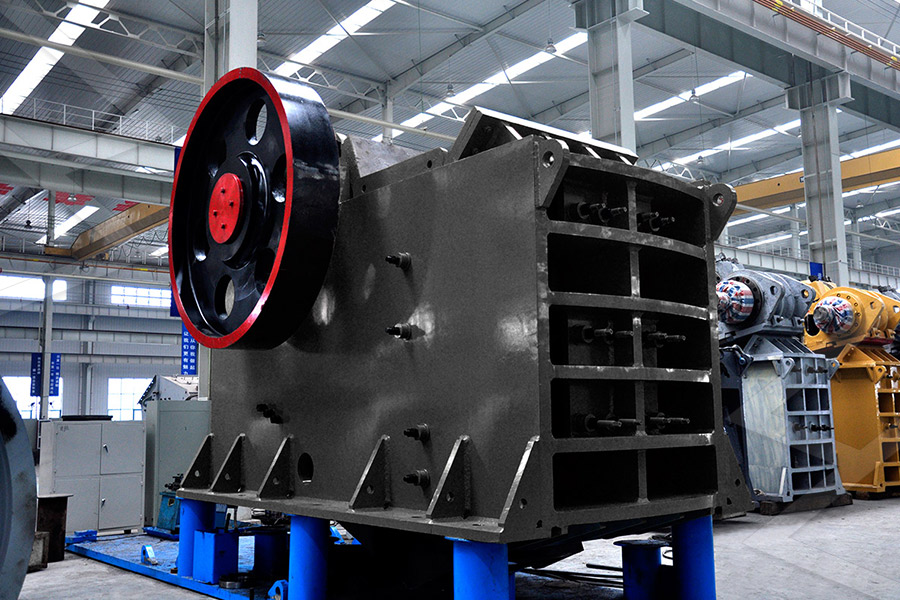

2024年9月22日 — Ball Mills: Ball mills are the most commonly used type of grinding mill They work by rotating a cylinder containing lead balls, called grinding media, at speeds of up to 700 revolutions per minute The ore is fed into the mill and as the cylinder rotates, the balls crush and grind the ore, causing the particles to break down in size Rod Mills:13′ X 21′ ALLIS CHALMERS BALL MILL, 2000 HP used Manufacturer: AllisChalmers Description 13′ x 21′ Allis Chalmers Ball Mill, 2000 HP Motor with Controls, Rubber Liners, Lubrication SystemsUsed Ball Mills (mineral processing) for sale in Ontario, 2023年11月23日 — Boosting productivity and quality in mining operations is a priority for many companies, and one of the key elements in achieving this goal is the use of highquality grinding media, specifically steel grinding ballsThese balls play a crucial role in the grinding of raw materials in cement plants, energy generating companies, ore mining, Steel Grinding balls an optimal choice for mining in ball mills